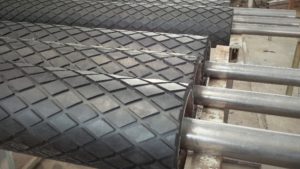

Cold Glued Pulley Lagging

Coating conveyor pulleys with lagging offers many benefits for the reliable running of the conveyor belt. It acts as a replaceable wear surface to prolong the life of the conveyor pulley whilst improving belt traction. This means the conveyor belt requires less tension prolonging the life of the belt and splice. Our lagging is fitted in sheet form so there is only one join. There is many thicknesses and profiles options available including FDA approved rubber products and adhesives.